The Backbone of Efficient Logistics: Understanding Warehouse Management Systems

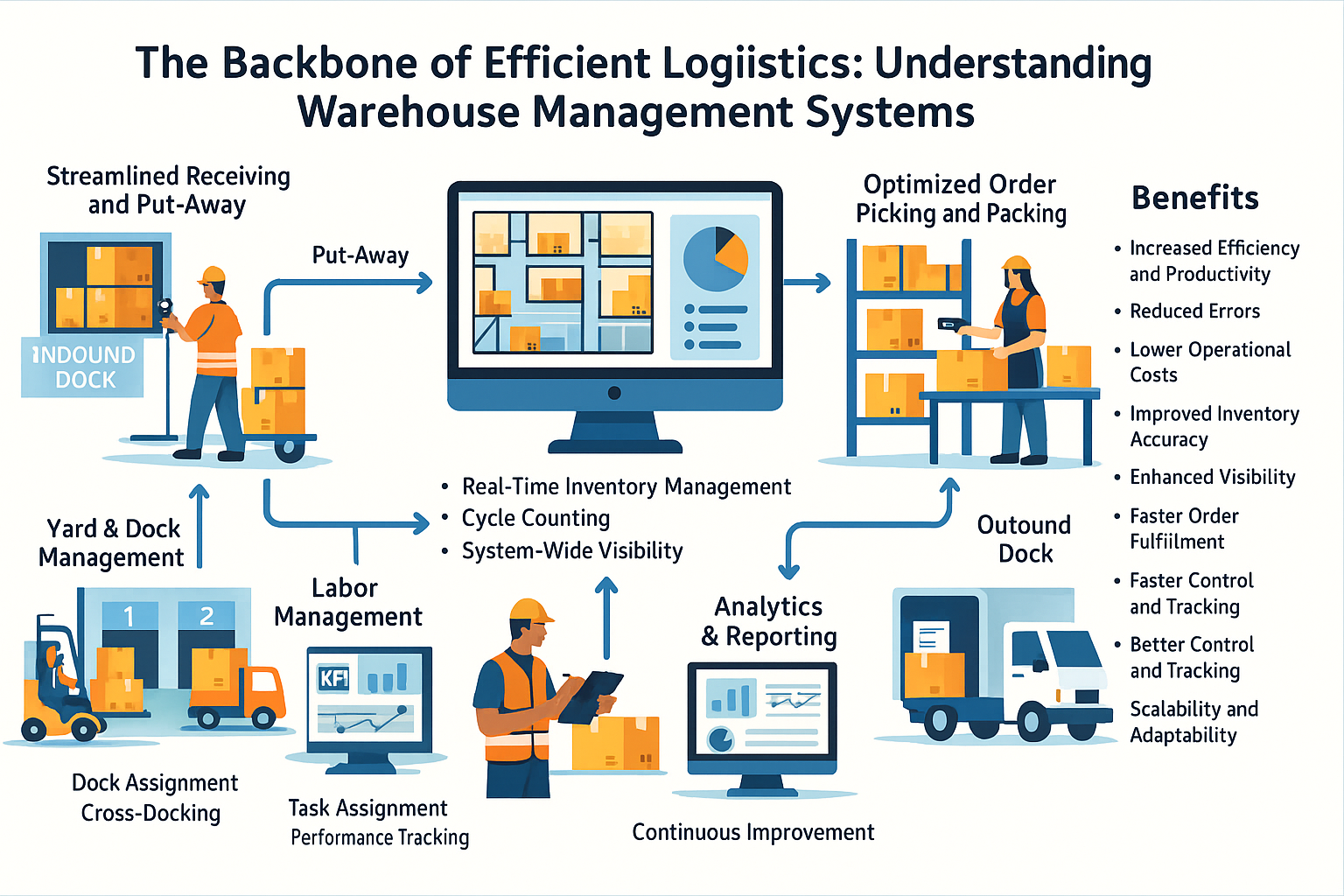

In today's fast-paced business environment, efficient warehouse operations are crucial for success. A key tool in achieving this efficiency is a Warehouse Management System (WMS). This software solution is designed to streamline and control the myriad of activities that occur within a warehouse, from the moment goods arrive to the instant they are shipped out. Think of it as the central nervous system for your warehouse, providing real-time visibility and control over your inventory and processes.

What Exactly Does a WMS Do?

A WMS is more than just an inventory tracker. It's a comprehensive system that optimizes various critical warehouse functions :

- Streamlined Receiving and Put-Away: When new stock arrives, the WMS guides the process of unloading, verifying, and storing items in the most efficient locations based on predefined rules and warehouse layout. This often involves technologies like barcode scanning to automatically update inventory records.

- Real-Time Inventory Management: Knowing exactly what you have, where it is, and in what quantity is essential. A WMS provides this real-time visibility across all warehouse locations, minimizing the risks of stockouts or overstocking. Many systems also support cycle counting for continuous inventory accuracy.

- Optimized Order Picking and Packing: Picking errors and delays can be costly. A WMS directs warehouse staff to the most efficient picking routes and methods, whether it's single order, batch, or zone picking. It can also integrate with packing processes to ensure accuracy and generate necessary shipping documents.

- Efficient Shipping Coordination: Getting orders out the door quickly and accurately is vital for customer satisfaction. A WMS often integrates with shipping and logistics software to automate the generation of shipping labels, bills of lading, and even shipment notifications. Real-time tracking capabilities allow businesses to monitor the journey of their goods.

- Enhanced Labor Management: Understanding labor costs and productivity is key to optimizing warehouse operations. A WMS can provide insights into worker performance, track labor costs, and even assist with task assignment to minimize wasted time and effort.

- Improved Yard and Dock Management: For warehouses with significant inbound and outbound truck traffic, a WMS can help manage the flow of vehicles, directing drivers to the correct loading docks and potentially supporting cross-docking operations for faster throughput.

- Data-Driven Insights and Analytics: A WMS automatically collects valuable data on all warehouse activities. This data can then be analyzed to track key performance indicators (KPIs) such as on-time shipping rates, inventory accuracy, and order cycle times, providing insights for continuous improvement.

The Benefits of Implementing a WMS

Investing in a WMS can bring a wealth of advantages to businesses of all sizes involved in warehousing and logistics :

- Increased Efficiency and Productivity: By automating and optimizing warehouse processes, a WMS helps reduce processing times and improves overall productivity.

- Reduced Errors: Automating tasks minimizes the risk of human error in picking, packing, and shipping, leading to greater accuracy and improved customer satisfaction.

- Lower Operational Costs: Better inventory management, optimized space utilization, and efficient labor management all contribute to significant cost savings.

- Improved Inventory Accuracy: Real-time tracking and cycle counting features ensure a more accurate picture of your inventory levels, reducing discrepancies and losses.

- Enhanced Visibility: A WMS provides a clear and up-to-date view of your entire inventory and warehouse operations, empowering better decision-making.

- Faster Order Fulfillment: Streamlined picking, packing, and shipping processes lead to quicker order turnaround times, improving customer service.

- Better Control and Tracking: With a WMS, businesses gain greater control over the movement of goods within the warehouse and throughout the supply chain.

- Scalability and Adaptability: Many WMS solutions are designed to scale with your business growth and can be customized to meet specific industry needs and workflows.

Choosing the Right WMS for Your Needs

The market offers a variety of WMS solutions, each with its own features and capabilities. When selecting a system, it's crucial to consider your specific business requirements, budget, and future growth plans. Factors to evaluate include the size and complexity of your warehouse operations, the level of customization needed, and whether you require a cloud-based or on-premise solution.

In conclusion, a Warehouse Management System is no longer a luxury but a necessity for businesses looking to optimize their warehouse operations, improve efficiency, reduce costs, and ultimately enhance customer satisfaction. By providing a centralized platform for managing all aspects of warehouse activity, a WMS empowers businesses to navigate the complexities of modern logistics and stay ahead in a competitive marketplace.